SITE MODEL MAKING

When we do urban design, we generally need to make a real model for deliberation. That lets us to get the characteristics of the site and the changes after design more directly.

Determine the scale between site and model

Firstly, we need to determine the scale of the model according to the size of the site. For example, a 1:100 model may be more appropriate for a one-hectare-site. In addition, terrain is also one of the factors affecting the scale. For example, if the terrain is very complex, it needs a larger scale to represent the characteristics of the terrain.

Selection of model materials

The selection of materials mainly considers the size of the model. One square meter model generally uses wood, while the two square meter model uses lighter foam plastic as the base. The architectural part of the model generally has no material restrictions. Wood, cardboard or foam plastic can be used. In this operation, we mainly chose foam plastic as the base, and we made wooden boards on it. This can save a lot of materials and avoid waste. But the disadvantage is that the base is very weak and takes longer.

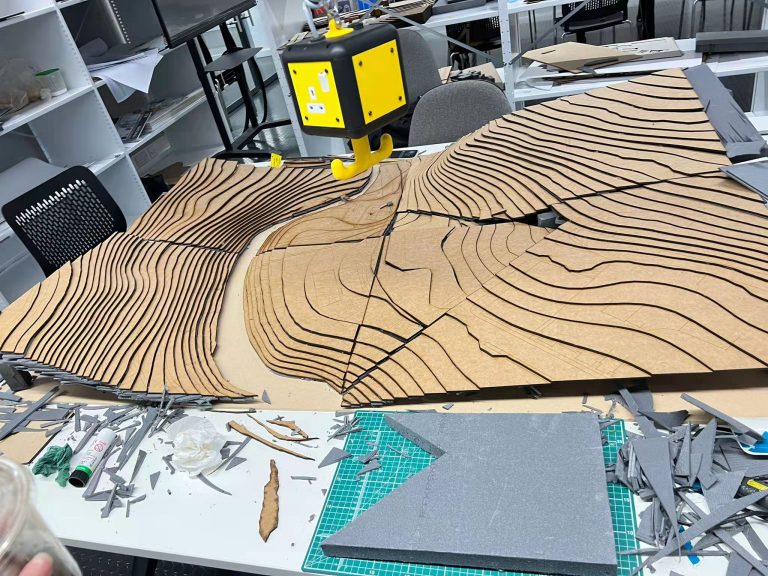

Model making

We first processed the CAD file of terrain. Then the wood board is cut by the cutting machine in workshop. Finally, according to the information on CAD, material is bonded with glue, and finally a complete model is generated. In the process of bonding the model, we choose the middle hollow bonding method for operation to save materials to the greatest extent. At high altitude, we will place some load-bearing foam blocks underneath.

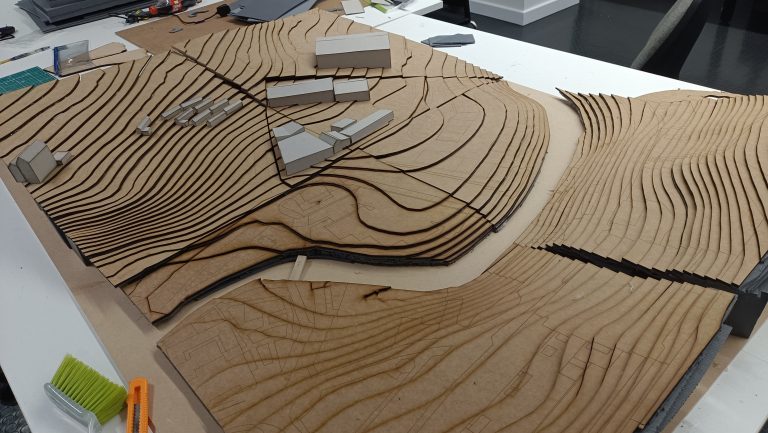

Value of model

The final model clearly shows the landform of our site and the relationship between architecture and site. We can deduce our design on the model. So as to design a more implementable scheme. Another advantage of using models for design is the presentation of solutions. An exquisite model can enable people who do not know the site to see the vision of the design at a glance.